Ford is cutting employee work hours due to the recent low demand for EVs and decline in electric vehicle sales. Ford’s Cologne, Germany, manufacturing plant is particularly affected by this decline. While addressing members of the German press, a Ford spokesperson clarified the reason for the cut in work hours.

The Ford spokesperson said, “The significantly lower than expected demand for electric vehicles, specifically in Germany, requires a temporary adjustment of production volumes at the Cologne Electric Vehicle Centre.”

ALSO READ: Workers Cry Out As John Deere Effects Massive Job Cuts in the Midwest and Moves Operations to Mexico

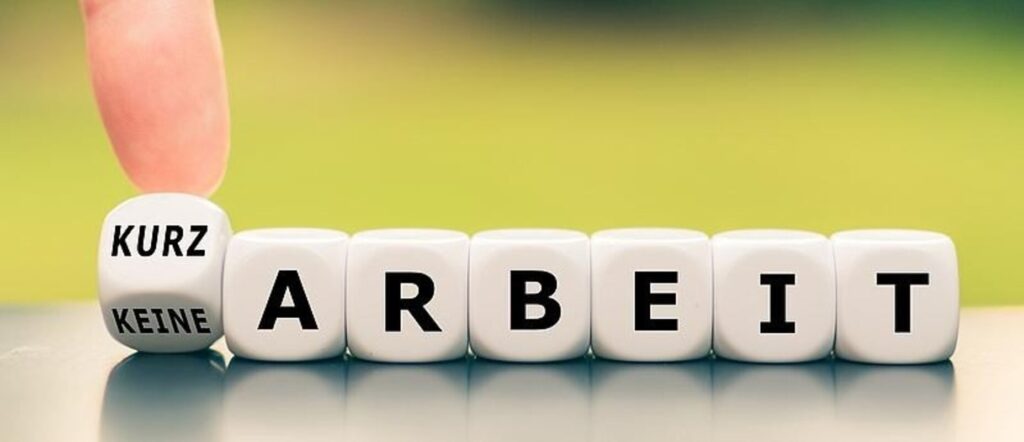

Application for Germany’s Kurzarbeit Scheme

Ford had to seek the approval of local labor regulators before effecting the changes in work hours. The carmaker’s application to the government bordered on temporarily converting the engagement terms of employees in Cologne.

Interestingly, the German Federal Employment Agency already has labor laws called the Kurzarbeit work program. During periods of low revenue or economic reverses, the Kurzarbeit program allows employers to temporarily cut employees’ work hours. This initiative consists of government incentives that encourages employers to maintain their workforce during reverses, instead of laying them off as a survival tactic.

Essentially, whenever the government approves an employer’s request to cut work hours under Germany’s Kurzarbeit Scheme, it takes up the responsibility of paying the employees 60% of their original pay. So, it is one of many forms of government incentives aimed at keeping the unemployment rate low.

EV Market Facing Declining Demand

Ford stated that it has approximately 4,000 workers at the Ford Cologne car manufacturing facility. However, the carmaker has a second facility in Germany, located in Saarlouis and employing some 6,200 workers.

The German news outlet that reported Ford’s work hours changes did not state the number of workers affected, or what percentage of their workload is being eliminated. This is an indication that the environmental awareness that birthed EVs does not necessarily translate to technology adoption.

Ford is not alone with respect to the low demand for EVs and quintessential supply chain issues. Indeed, many EV makers are similarly scaling back on their production outputs. When market challenges like price sensitivity cause the demand for your product to drop, it would be counterintuitive to increase production. Instead, several carmakers, including Ford, are increasing their throughput for hybrid cars. Many carmakers find this a better investment over increasing charging infrastructure and killing range anxiety.

Carmakers’ decision to invest resources in the manufacture of hybrid cars is not spontaneous but a response to consumer preferences for that car variant. A common narrative among EV reviewers is that these green innovations are quite expensive. Consequently, a lot of EV lovers who find the pricing overwhelming and range anxiety perplexing often opt for the usually cheaper hybrid option.

Cancelled Electric SUV and Pickup Truck Delays

A few months ago, Ford opted to change plans on its grand three-row fully electric SUV design sequel to the slow electric vehicle sales. Similarly, the American carmaker has placed the production of its next electric pickup truck on hold. Instead, Ford reached a compromise to sidestep the supply chain issues, by opting to replace its proposed fully electric SUVs with hybrid variants. The carmaker went public with this detour in August, as announced by the company’s finance chief, John Lawler.

Ford probably has its production lines already tailored for the production of fully electric SUVs. The sudden change of production strategy from fully electric to hybrid, in line with consumer preferences, is estimated to cost Ford roughly $2 billion.

Third-Quarter Earnings Reflect Challenges

Ford reported its Q3 earnings on October 28, with revenue standing at $46 billion and net income hovering around $900 million. When compared year-on-year to the company’s Q3 earnings from 2023, Ford’s income was approximately $300 million short.

While the decline in earnings may be partly due to the low demand for EVs, Ford is doing all that is organizationally possible to eliminate the effect of price sensitivity and similar market challenges. For example, the statement of Ford CEO and President, Jim Farley, in the Q3 earnings report suggests that much. His statement partly reads, “We are in a strong position with Ford+ as our industry undergoes a sweeping transformation.”

CEO Farley’s Strategic Vision for Ford’s Transformation

For those who have not caught on to the Ford+ gist, it is a business strategy by the carmaker to focus its effort on innovative and profitable vehicles and systems. So, Ford+ basically splits the company into three business segments; Ford Blue, Ford Model-e and Ford Pro.

Of Ford Pro, Farley had this to say: “We have made strategic decisions and taken the tough actions to create advantages for Ford versus the competition in key areas like Ford Pro, international operations, software, and next-generation electric vehicles.”

ALSO READ: Top 8 Largest Tech Company Layoffs of 2024

Ford Pro is more like a vehicle fleet management system that allows commercial owners of Ford vehicles to seamlessly manage their automobiles. In other words, Ford is slowly delving into the software and charging infrastructure business, like Elon Musk’s Tesla.

However, given all the talk about breaking even by cutting work hours in some of their facilities, it may come as a surprise that Ford has already cut thousands of jobs. These series of layoffs were particularly prominent when Ford started making environmental awareness a priority and joined the EV technology adoption bandwagon. Supply chain issues and low demand for EVs plaguing carmakers were also complicit in the downsizings.